• The Patented EZ StackBlocks System is a unique and unmatched design in the dry stacking block industry with an Optional locking starter strip device.

• The Optional starter strip begins the uniformed stacking process of the building. Once the starter strip is leveled, squared, lag bolted to the footing and the first row of block is installed, the easy stacking begins. Or the first row of block can be installed using traditional mortar attachment construction.

– EZ Stack Blocks allows the laborer to install each block interlocking with the one before it, assuring proper alignment.

– After the first row of block is installed with or without the use of the metal starter strip.

• The transition or corner block adds a feature unlike any other block system, easily tying adjacent walls together row by row.

• This is a complete building system for foundations, self standing buildings, internal wall partitions for dividing warehouse, manufacturing spaces that require temporary or permanent walls. It also has many other uses.

The following Patents have been issued in support of EZ Stack Blocks

• U.S. patent # 7,610,730 Non-Provisional Patent issued on 11-02-2009

• U.S. patent #D624,205 Design patent issued on 09-21-2010

• Title: Interlocking Masonry Block

• U.S. patent #8,800,230 issued on 08-12-2014

• Title: STACKING MASONRY BLOCK SYSTEM WITH TRANSITION BLOCK AND UTILITY GROOVE RUNNING THERETHROUGH

• Dry Stack block process is an acceptable building process and is referenced in standard building permit requirements.

• Specification ASTM C946 - 10

– Standard Practice for Construction of Dry-Stacked with Surface Bonded Walls.

– This practice covers material, workmanship, and construction procedures for applying surface bonded mortar to both sides of dry stacked concrete masonry units (CMU).

– Also covers the use of rebar and grout filled vertical cores in your block wall.

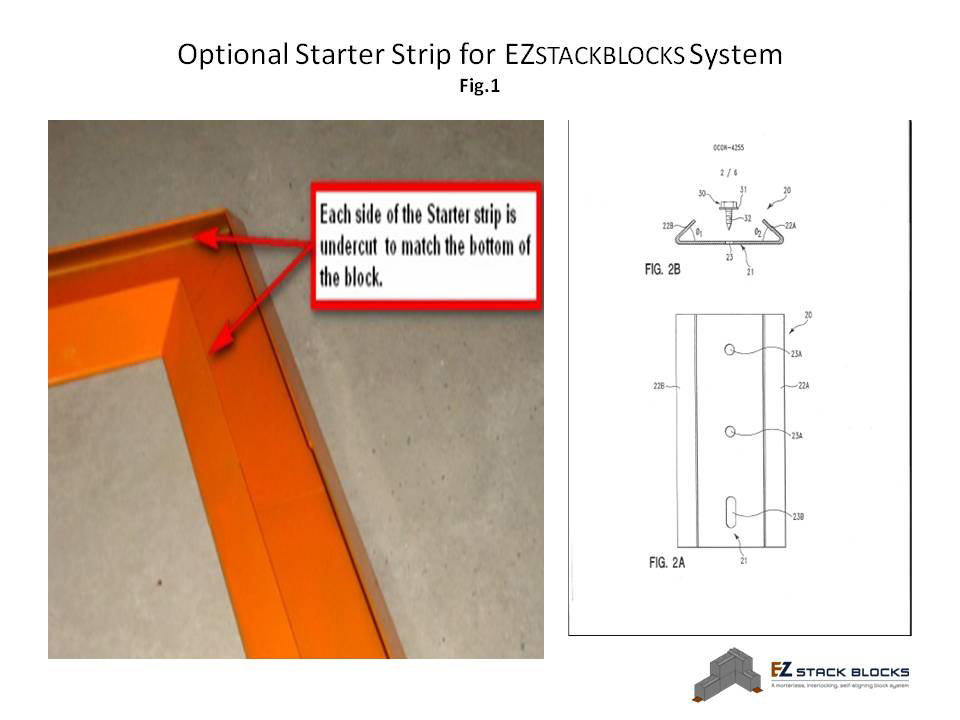

• Metal Starter Strip:

– This Optional metal strip is formed to mate with the bottom side of the linear and corner blocks.

– It is installed and squared, then secured to the footing or foundation slab with lag bolts.

See fig. 1.

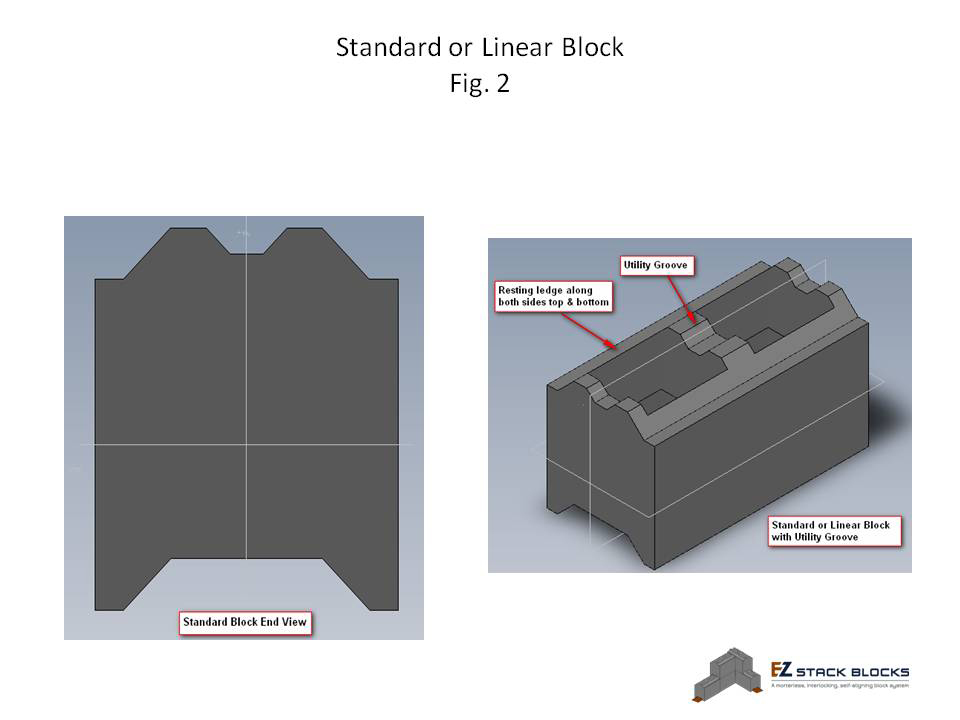

• Linear Block for Continuous Wall Building:

– All blocks have a tongue and groove feature top and bottom. When a block is dry stacked it will align to it’s mating block, aligning and locking each block together.

See fig. 2.

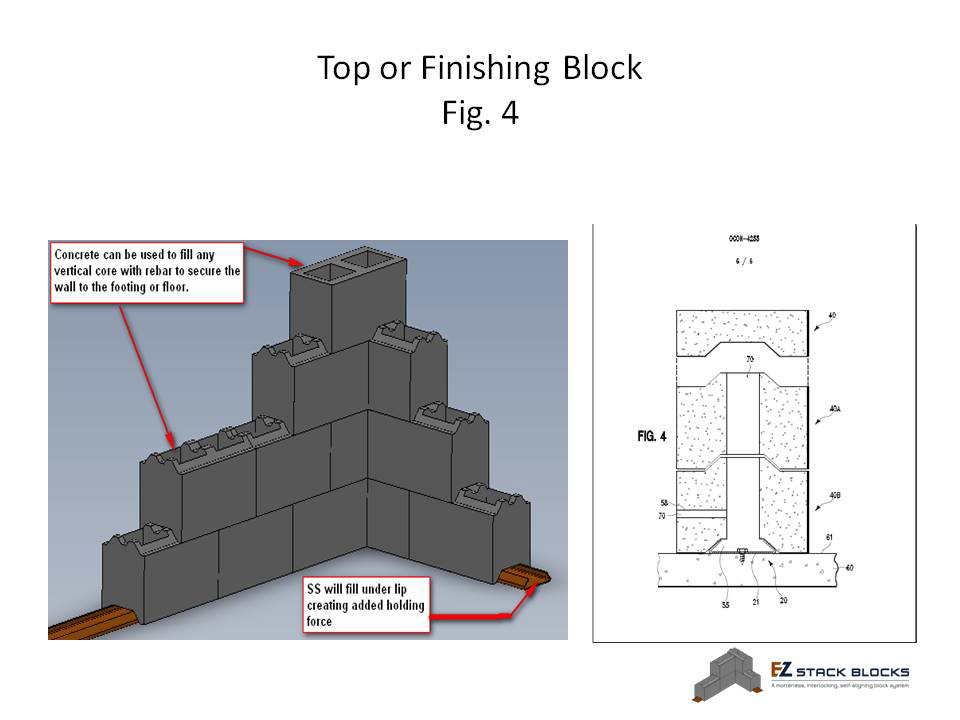

• Transitional or Corner Block:

– The corner block is shaped to connect each adjoining row connecting and locking each row of block for a continuous wall. See fig. 3 . & 4.

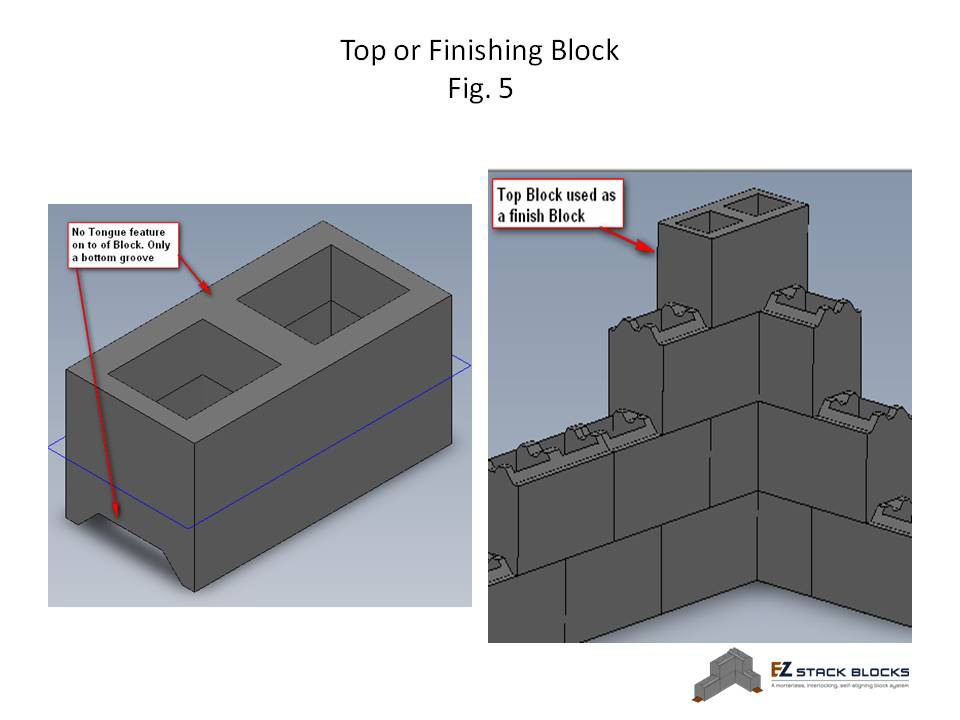

• Top Block:

– The Top or Finishing block is optional and has a flat top with the bottom shaped groove feature. See fig. 4. & 5.

See fig. 4.

See fig. 5.